Over the course of a year, the safety agency investigated 10 preventable deaths and more than 20 preventable injuries caused by various accidents involving scissor lifts. Investigations found that the majority of injuries and deaths involving scissor lifts were due to employers not providing adequate training on the dangers of scissor lifts.

Employers need to assess the workplace to identify all possible hazards in order to select appropriate equipment for the task. Employers using scissor lifts need to assess and implement effective control measures to address fall protection, stability and positioning issues.

Only trained workers are allowed to use scissor lifts and employers should ensure that these workers can prove that they can use scissor lifts properly. The use of safety scissor lifts includes proper maintenance of equipment, following manufacturer's instructions, providing workers with training and required personal protective equipment (PPE), and implementing safe work practices.

Here are some safety tips for scissor elevators:

Fall protection - Scissor lifts must be fitted with guardrails to prevent workers from falling. Employers shall train workers to:

Stabilization - The employer should ensure that scissor lifts are stable and do not capsize or collapse. To ensure safe and stable conditions for the use of scissor lifts, some safe working practices include:

Positioning - Workplaces where scissor lifts are used present a risk of breakage that may expose nearby workers, even those who do not work on scissor lifts. Scissor lifts are similar to vehicles and other mobile equipment on site and have a risk of breakage. Employers should train workers to be vigilant in the following situations:

Avoiding electric shocks, arc flashes and heat burns are important when using scissors safely near live wires. Electric shock can occur even if neither the scissor lift nor the worker is in contact with the power line because the arc or current from the power line can jump onto the scissor lift or the worker. Take traffic control measures around scissor lifts to prevent other staff or vehicles from getting too close.

Collapse - Although rare, the collapse of scissor lifts can be prevented if employers

If you have the need to purchase scissor lifting platform, you can contact us at any time.

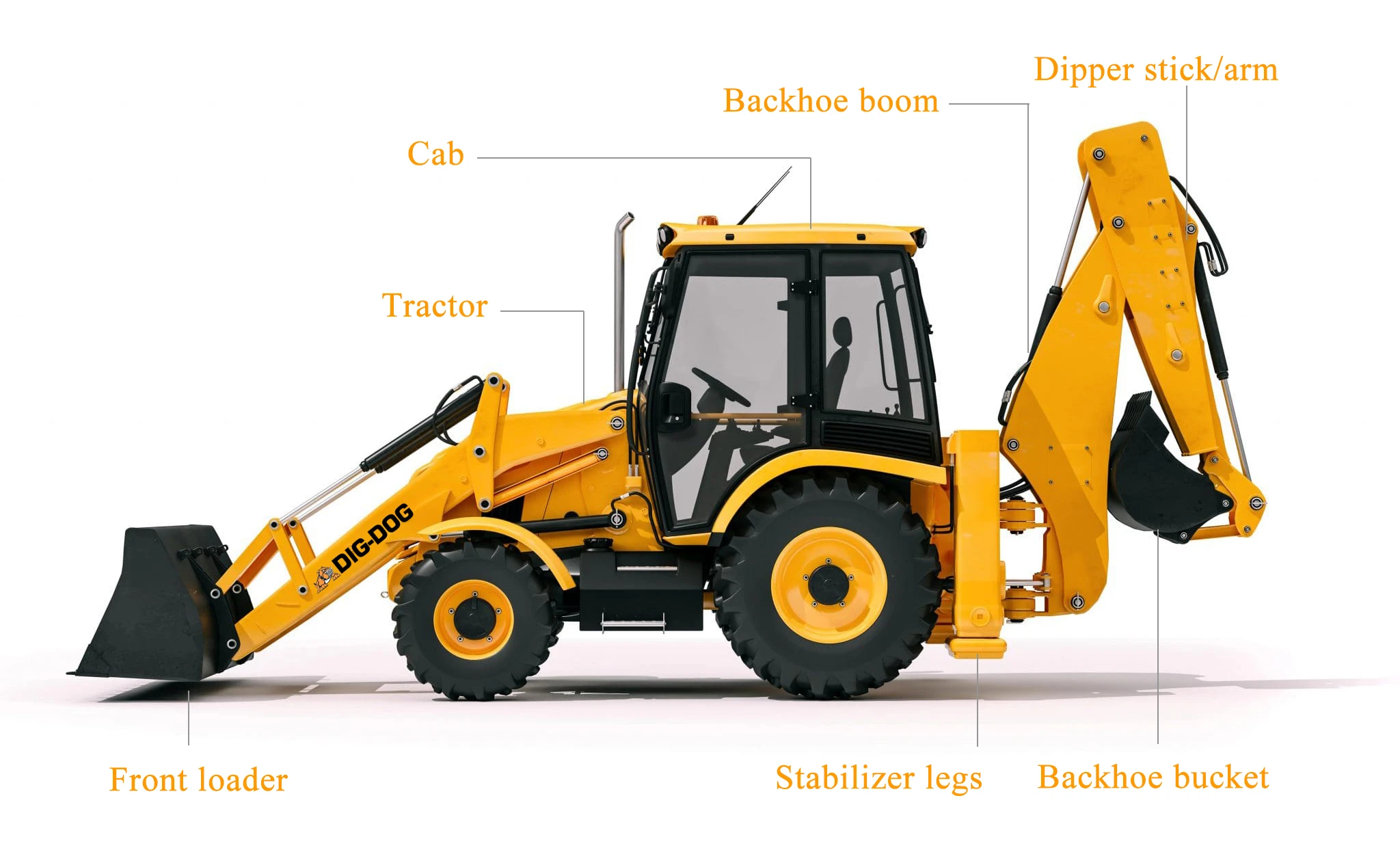

What is a Backhoe? Its Uses & Market Development

What is a Backhoe? Its Uses & Market Development

What Is The Difference Between An Excavator And A Backhoe?

What Is The Difference Between An Excavator And A Backhoe?

Choosing the Right Loader Truck for Your Business Needs

Choosing the Right Loader Truck for Your Business Needs

Unveiling the Top 10 Must-Have Construction Vehicles for Your Business

Unveiling the Top 10 Must-Have Construction Vehicles for Your Business